Electromechanical Energy Consumption Monitoring Solution

28 Nov 2025

1. Overview

With the deepening of global energy conservation and emission reduction strategies and the increasing emphasis on enterprise operational efficiency, effective monitoring and management of electromechanical energy consumption have become core demands for industries, commerce, and public institutions. Our Electromechanical Energy Consumption Monitoring Solution is designed to address the pain points of unclear energy consumption structure, low management efficiency in traditional electromechanical systems. By integrating advanced sensing technology, communication technology, and data analysis capabilities, the solution realizes full-process, real-time, and refined monitoring of energy consumption of electromechanical equipment (such as air conditioners, water pumps, elevators, and power distribution systems), providing reliable data support and decision-making basis for enterprises to achieve energy conservation, cost reduction, and green operation.

2. Core Architecture

The solution adopts a four-tier architecture of "Perception Layer - Communication Layer - Platform Layer - Application Layer", ensuring stable operation, efficient data transmission, and flexible application expansion.

2.1 Perception Layer

As the data source of the entire monitoring system, this layer is composed of a series of high-precision energy monitoring devices, including: multi-circuit power meters, current transformers (CT), voltage transformers (VT), temperature and humidity sensors, etc. These devices collect key energy consumption data (voltage, current, power, energy) and operating status parameters (equipment running time, load rate, fault alarms) of electromechanical equipment in real time, with a data collection accuracy of up to 0.5S level, meeting the requirements of refined energy management.

2.2 Communication Layer

Responsible for transmitting the data collected by the perception layer to the platform layer stably and efficiently. It supports multiple communication modes such as RS485, Ethernet, LoRa, NB-IoT, and 4G, adapting to different on-site environments (such as complex wiring in industrial workshops, wide coverage in commercial complexes, and remote areas with weak signals). The communication protocol adopts industry-standard Modbus RTU/TCP, MQTT, etc., ensuring good compatibility and interoperability of data. At the same time, it has functions such as data encryption and breakpoint resume transmission to ensure the security and integrity of data during transmission.

2.3 Platform Layer

As the core of the solution, it undertakes functions such as data receiving, storage, processing, and analysis. It is built based on cloud-native technology, supporting both on-premises deployment and cloud deployment to meet the different needs of enterprises for data security and operation and maintenance. The platform integrates powerful data processing engines, which can clean, filter, and aggregate massive energy consumption data, and use data mining algorithms to analyze energy consumption trends, abnormal energy consumption identification, and energy-saving potential evaluation. In addition, it provides open APIs to facilitate integration with enterprise ERP, BMS (Building Management System), and other systems to realize unified management of energy data and business data.

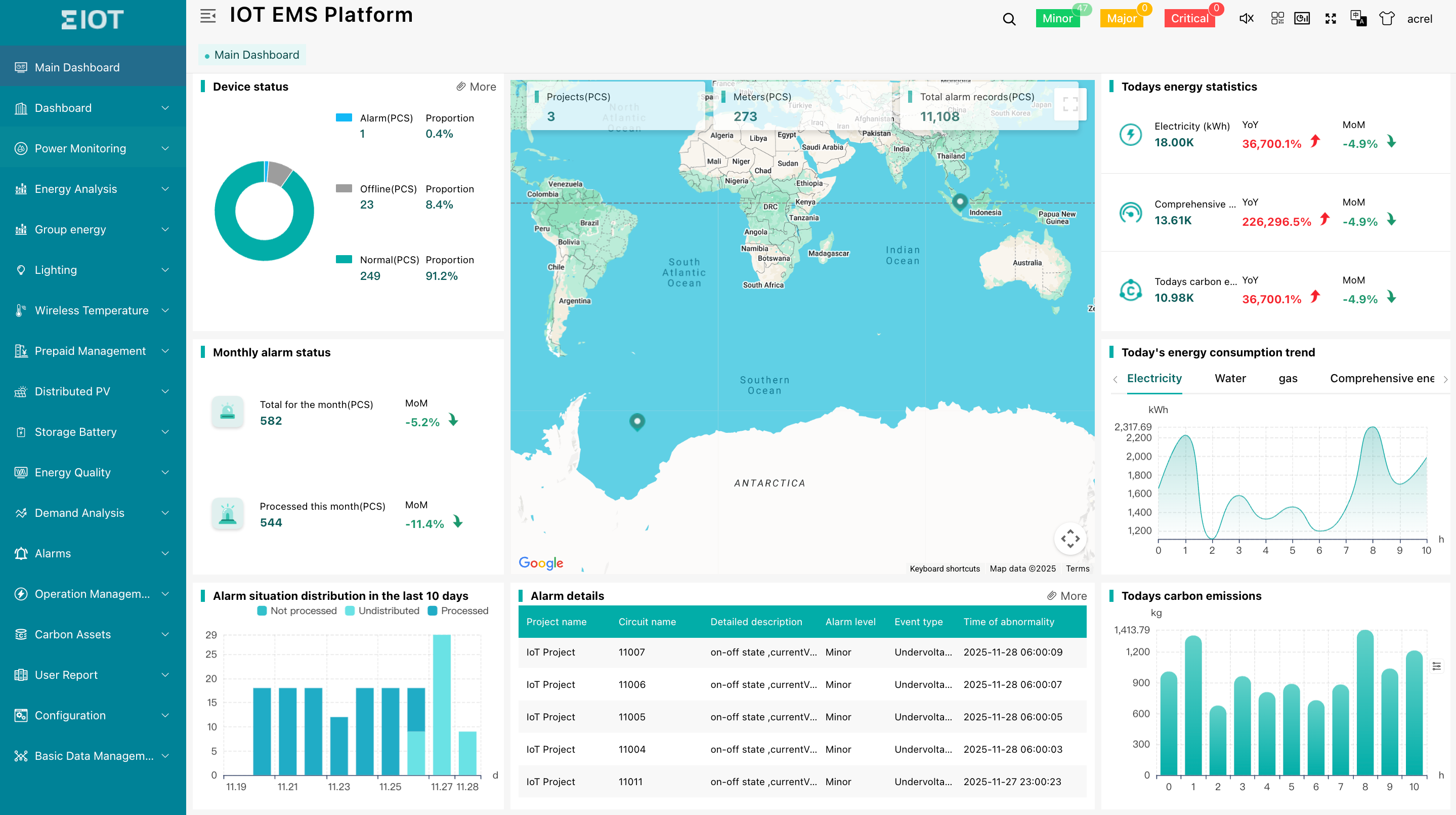

2.4 Application Layer

Provide user-oriented practical application functions through a visual interface (Web end, mobile App, large screen monitoring). The main modules include energy consumption monitoring, statistical analysis, report generation, fault alarm, etc. Users can intuitively grasp the energy consumption status of electromechanical equipment through the interface, and realize refined management of energy consumption through functions such as remote monitoring and automatic alarm.

3. Core Functions

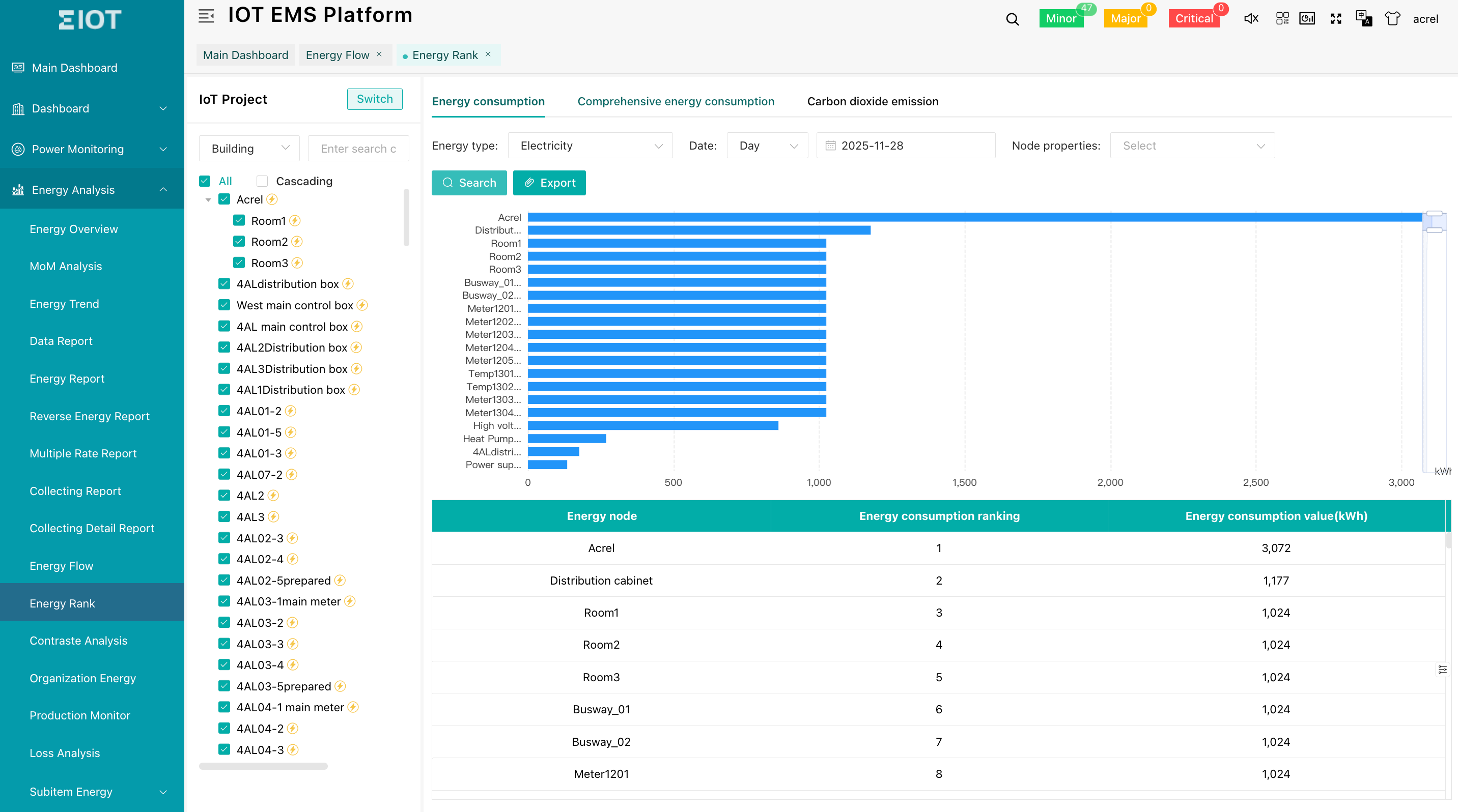

3.1 Real-Time Energy Consumption Monitoring

Real-time display of electrical energy consumption data of various electromechanical equipment and systems, supporting multi-dimensional monitoring by equipment type, area, department, and time period. The interface adopts visual charts (line charts, bar charts, pie charts) to intuitively reflect energy consumption changes, helping users quickly grasp the energy consumption dynamics of the entire park/enterprise.

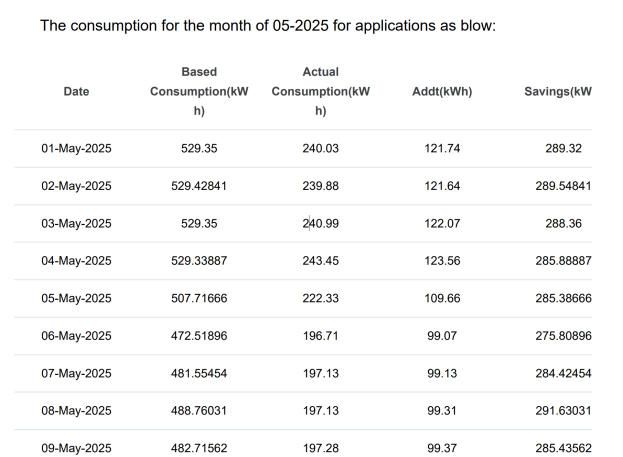

3.2 Statistical Analysis & Report Generation

Automatically complete statistical analysis of electrical energy consumption data by hour, day, month, and year, and generate standardized energy consumption reports (such as energy consumption summary report, energy consumption comparison report). The reports can be exported in Excel, PDF and other formats, which is convenient for enterprises to carry out energy consumption assessment and meet the requirements of relevant national energy conservation supervision.

3.3 Abnormal Alarm & Fault Diagnosis

Set reasonable energy consumption thresholds and operating parameter ranges for electromechanical equipment. When abnormal energy consumption (such as excessive energy consumption, sudden power failure) or equipment failure (such as abnormal load, overheating) occurs, the system will immediately send alarms through SMS, email, App push, and on-site sound and light prompts. At the same time, it can assist in fault location through historical data analysis, reducing the time for fault handling.

3.5 Remote Control & Intelligent Regulation

For electromechanical equipment that supports remote control (such as frequency converters, intelligent air conditioners), the system can realize remote switching, load adjustment, and operating mode setting. It can also formulate intelligent regulation strategies based on actual needs (such as adjusting the temperature of air conditioners according to the number of on-site personnel), realizing energy-saving operation of equipment without manual intervention.

4. Technical Advantages

4.1 High Precision & Reliability

Adopt high-precision energy monitoring devices and mature communication technologies, with data collection accuracy up to 0.5S level and data transmission stability rate over 99.9%, ensuring the authenticity and reliability of energy consumption data.

4.2 Strong Compatibility & Scalability

Support multiple communication protocols and device types, and can be seamlessly connected with electromechanical equipment of different brands and models. The platform adopts a modular design, which can flexibly expand functions (such as adding new energy monitoring modules, intelligent control modules) according to the development needs of enterprises.

4.3 Easy Deployment & Simple Operation

The monitoring devices are easy to install, and the communication layer supports wireless communication modes, reducing on-site wiring work and construction costs. The application layer adopts an intuitive visual interface, with simple operation logic, and users can master the use method through simple training.

4.4 Comprehensive Data Security

Adopt multiple security measures such as data encryption, access control, and log management to ensure the security of electrical energy consumption data during collection, transmission, and storage. At the same time, it supports data backup and disaster recovery functions to prevent data loss.

5. Applicable Scenarios

The solution is widely applicable to various scenarios that require refined management of electromechanical energy consumption, including:

- Industrial Parks & Factories: Monitoring of energy consumption of electromechanical equipment such as production lines, air compressors, and water pumps in industrial workshops.

- Commercial Complexes & Shopping Malls: Monitoring of energy consumption of central air conditioning, elevators, lighting, and power distribution systems in commercial buildings.

- Hospitals & Schools: Monitoring of energy consumption of medical equipment, air conditioning, and water supply and drainage systems in public institutions.

- Data Centers: Monitoring of energy consumption of UPS power supplies, precision air conditioners, and power distribution systems in data centers, ensuring safe and energy-saving operation of data centers.

- Residential Communities: Monitoring of energy consumption of public electromechanical equipment such as water pumps, elevators, and public lighting in residential areas.

6. Service Commitment

We provide a full-cycle service system including pre-sales consulting, on-site investigation, program customization, installation and commissioning, personnel training, and after-sales maintenance. Our professional technical team will provide 7×24-hour technical support to ensure the stable operation of the system. At the same time, we will regularly update the system software and provide continuous function optimization services to help enterprises continuously improve energy management efficiency and realize sustainable development.

News