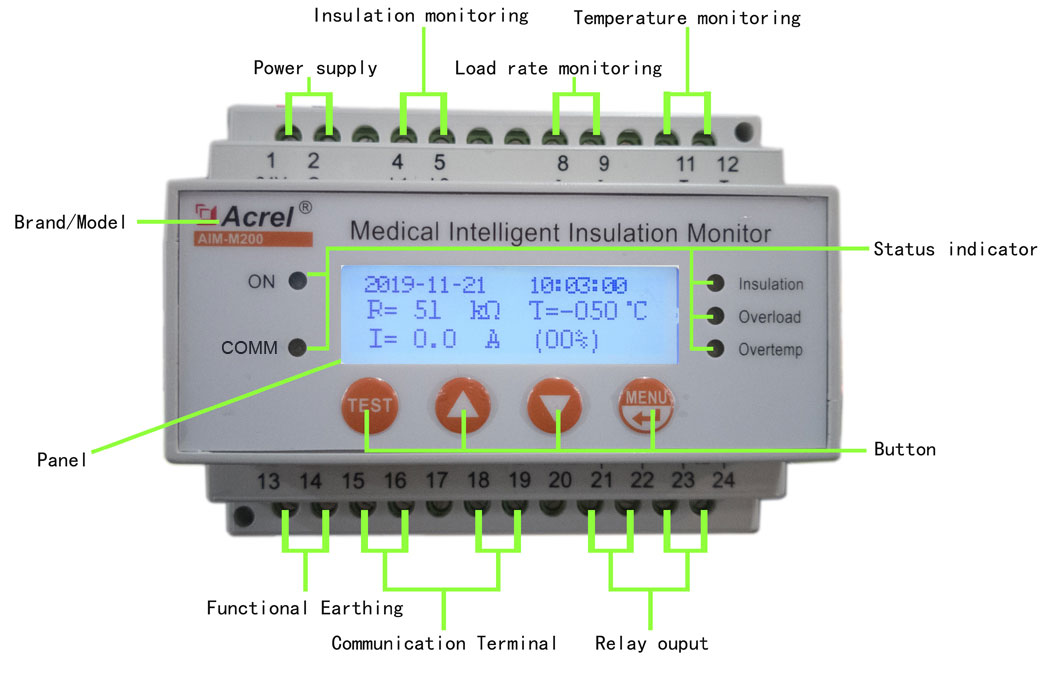

● Insulation monitoring for medical IT systems

● Load and temperature monitoring of isolation transformer

● Device disconnection monitoring

● LED indicators: On, Insulation, Overload, Overtemp

● Alarm relay output

● Test button

● Insulation fault location

● RS485 (MODBUS-RTU) + CAN

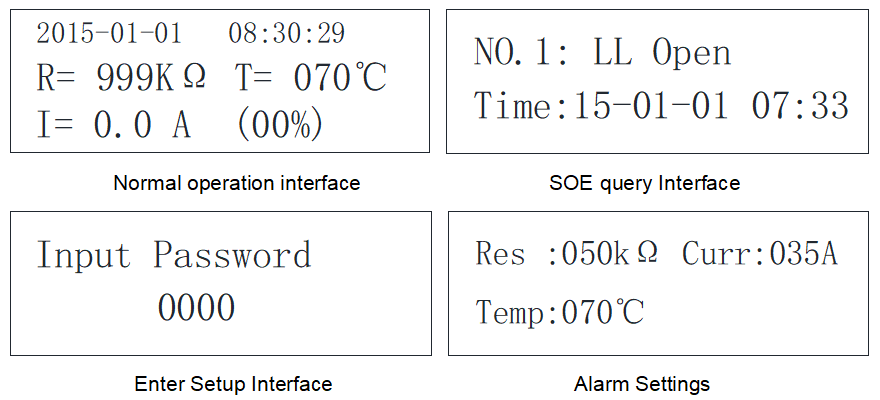

Display

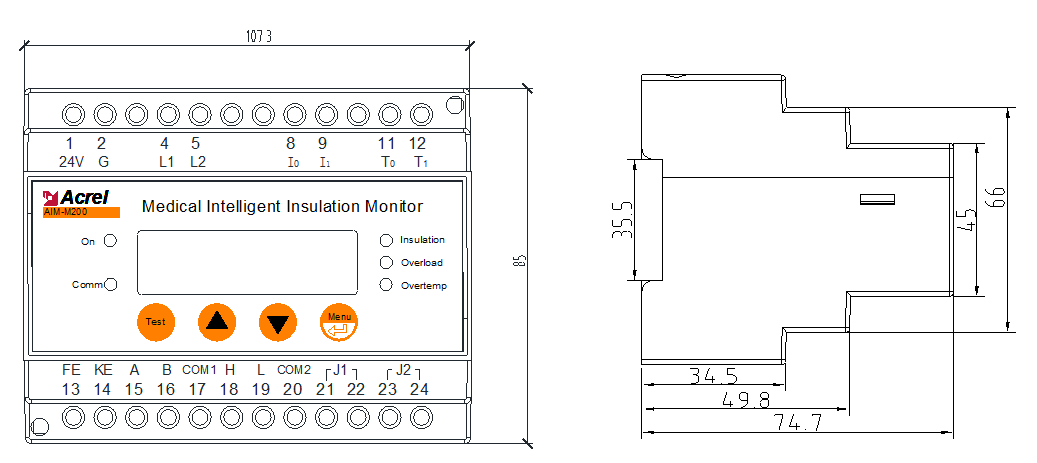

Dimension

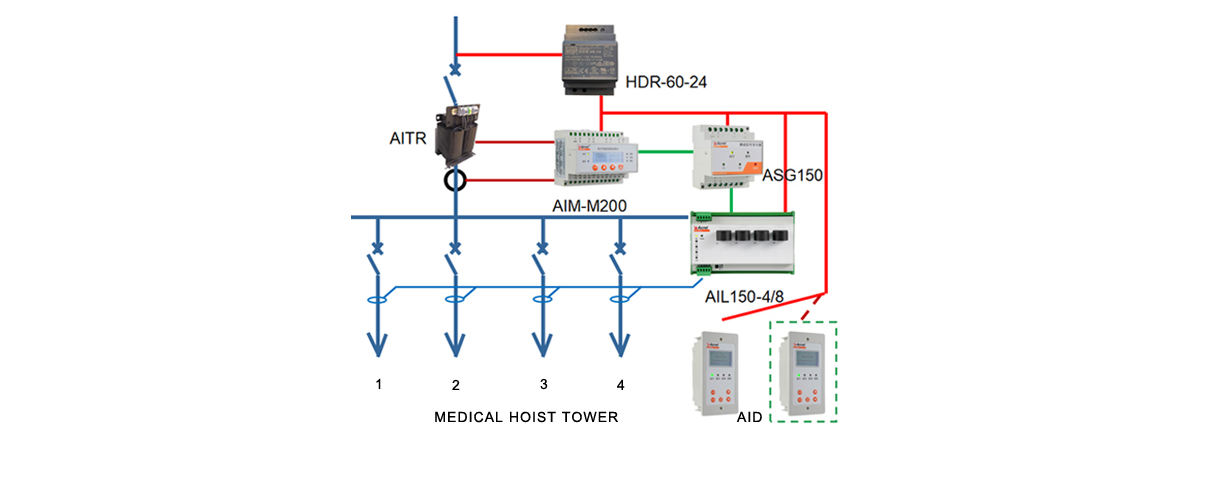

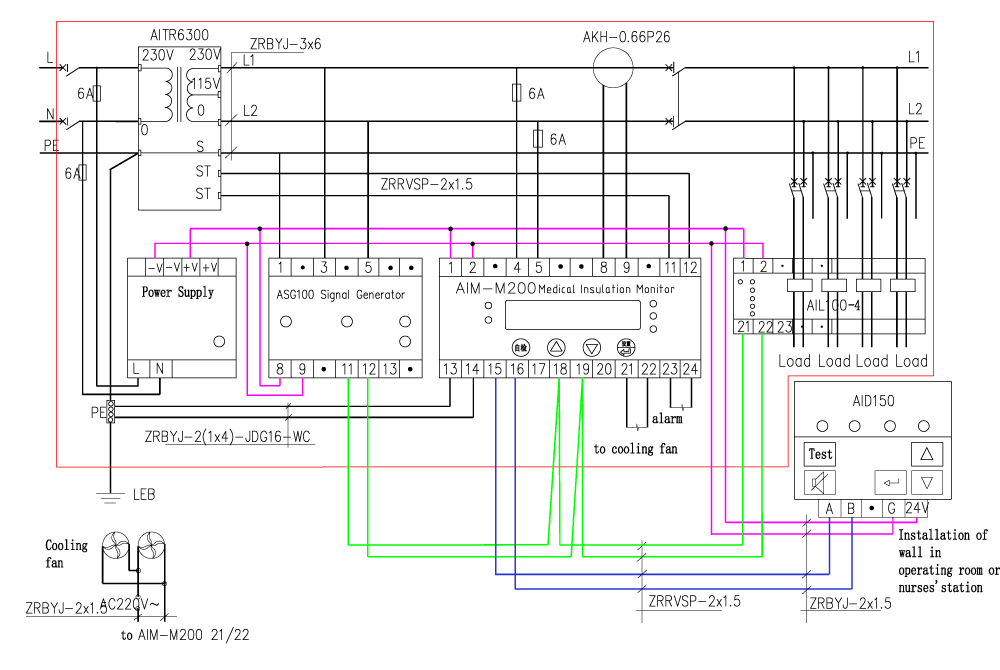

Application

Typical Solution

Technical parameters

|

AUX Power |

Voltage |

DC 18-36V |

Temperature monitoring |

Thermal resistor |

2 Pt100 |

|

Power consumption |

≤3VA |

Measuring range |

-50~+200℃ |

||

|

Insulation monitoring |

Resistance measuring range |

10-999kΩ |

Alarm value range |

0~+200℃ |

|

|

Response value |

50-999kΩ |

Alarm output |

Output mode |

2 Relays |

|

|

Relative uncertainty |

±10% |

Contact rating |

AC 250V/3A DC 30V/3A |

||

|

Response time |

≤3s |

Environment |

Operating temperature |

-10~+55℃ |

|

|

Permissible system leakage capacitance Ce |

≤5uF |

Transport temperature |

-25~+70℃ |

||

|

Measuring voltage Um |

≤12V |

Storage temperature |

-25~+70℃ |

||

|

Measuring current Im |

≤50uA |

Relative humidity |

5%-95%,No condensation |

||

|

Impedance Zi |

≥200kΩ |

Altitude |

≤2500m |

||

|

Internal DC resistance Ri |

≥240kΩ |

IP degree |

IP30 |

||

|

Permissible extraneous DC voltage Ufg |

≤DC280V |

Rated impulse voltage / pollution degree |

4KV/Ⅲ |

||

|

Load current monitoring |

Measuring Value |

2.1-50A |

EMC |

IEC 61326-2-4 |

|

|

Alarm Value |

5-50A |

Communication |

CAN |

||

|

Measuring accuracy |

±5% |

RS485(Modbus-RTU) |

|||

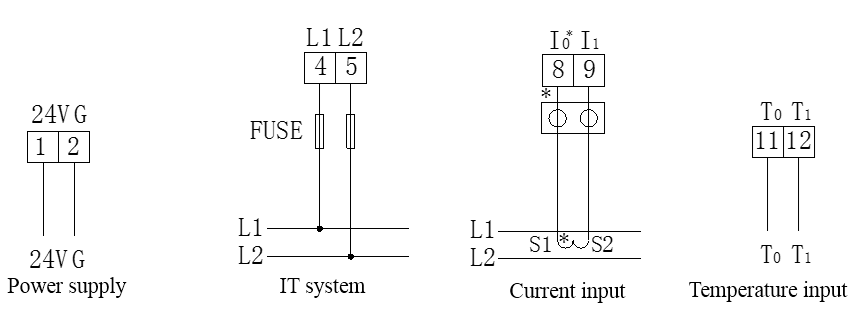

Wiring and Installation

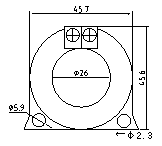

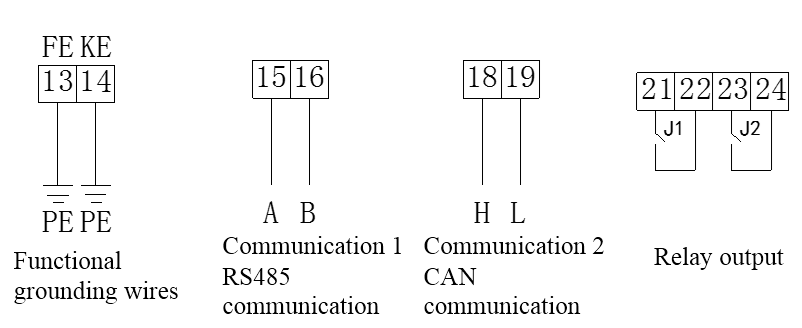

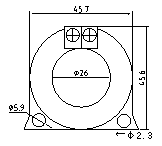

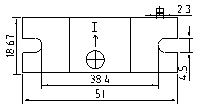

The installation size of AKH-0.66P26 is shown in the following figure:

-

Front view

-

Bottom view

Operation and Display

LED indicator instructions

|

Indicator status |

Instructions |

|

On |

When the device is in normal operation, the indicator flashes, and the flickering frequency is about once a second. |

|

Comm |

Indicate communication status, when there is data transmission, the indicator flashes. |

|

Insulation |

When the insulation resistance exceeds the alarm setting value, or when FK/LL is disconnected, the indicator flashes to alarm. |

|

Overload |

When the system load current exceeds the alarm setting value, the indicator flashes to alarm |

|

Overtemp |

When the transformer temperature exceeds the alarm setting value or the temperature sensor wiring is disconnected, the indicator flashes to alarm. |

Button function descriptions

|

Buttons |

Button function |

|

|

In non-programming mode, press this key to enter programming mode. In programming mode, it is used as a confirmation key. |

|

|

In non-programming mode, it is used to query the SOE , check the version information, or to register addresses to AID200. In programming mode, it is used to add or subtract values or switch settings. |

|

|

In operation state, used to start the self-test function of instrument. In other state, used as a return key. |

Data settings

|

First menu |

Second menu |

Range and description |

|

Set Comm |

485 Ad |

1-247 |

|

Baud |

4800,9600,19200 |

|

|

Can Ad |

1-110 |

|

|

LOCAT |

YES,NO |

|

|

Set Alarm |

Res |

50-999 |

|

Irms |

14,18,22,28,35,45 |

|

|

Temp |

0-200 |

|

|

Set Time |

Date

|

Year-month-day |

|

Time |

Hour-minute-second |

|

|

Set Others |

Pass

|

0000-9999 |

|

Contra |

0-63 |

|

|

BL |

1-99 |

|

|

ClrSOE |

Clear the fault record |

Common problems

Make sure the connection is correct before the system is powered on. For common problems, according to the fault phenomena in the table below, targeted investigation can be carried out.

|

Fault phenomenon |

Possible causes and troubleshooting |

|

LCD: LL open, and the Insulation indicator is lit. |

Terminal 4 and terminal 5 of AIM-M200 are not reliably connected to L1 and L2 of the IT system. Check the connection and make sure it is reliable. |

|

LCD: FK open, and the Insulation indicator is lit. |

Terminal 13 and terminal 14 of AIM-M200 are not reliably connected to LEB. Check the connection and make sure it is reliable. |

|

LCD: TC open, and the Overtemp indicator is lit. |

Terminal 11 and terminal 12 of AIM-M200 are not reliably connected to the two ST terminals of the isolation transformer. Check the connection and make sure it is correct. |

|

LCD: insulation fault, and the Insulation indicator is lit. |

At least one of the L1 and L2 wires in IT system has grounding fault, which can be restored to normal after removal. |

|

The device can't light up. |

The working power supply of AIM-M200 is not connected properly. Check the connection of terminals 1 and 2 and make sure it is correct |

Note: All the above faults should be checked by power off, and the wiring should be adjusted until everything is normal.

Diagram