-

70 Utility Model Patents

-

5 TradeMarks

-

93 Design Patents

-

147 Computer Software Copyrights

-

18+ Years Experience

-

3000+ Staffs

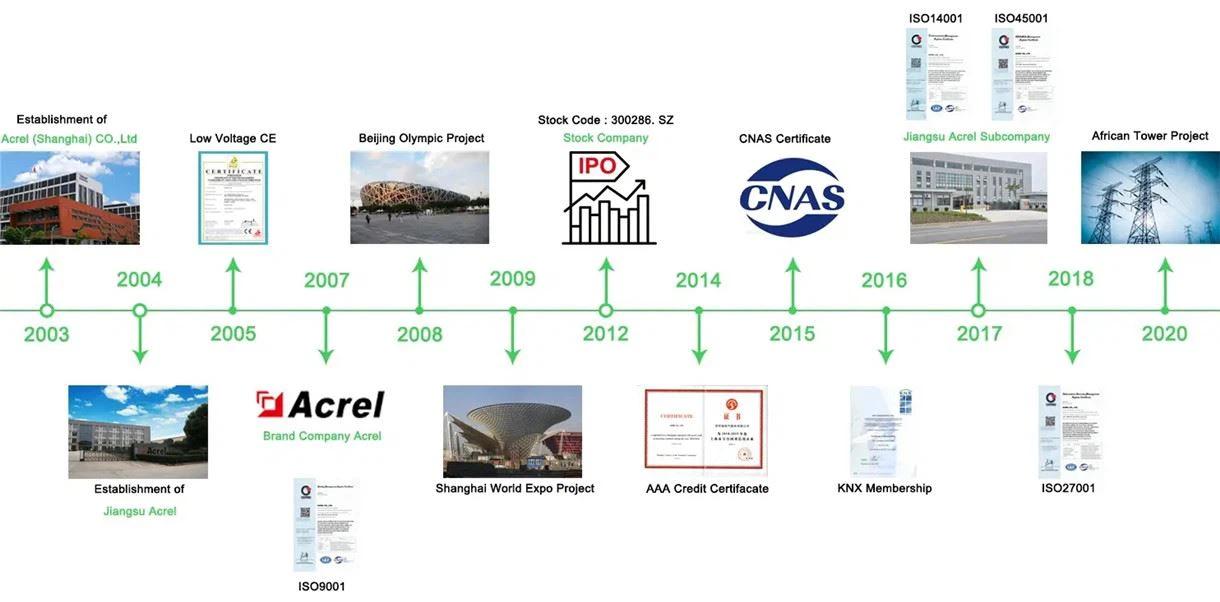

2003- Acrel's headquater was founded in Shanghai.

2006- Acrel's factory was founded in Jiangsu Province.

2007- Acrel started to provide solutions for users.

2012- Acrel listed on Shenzhen Stock Exchange (300286.SZ), and became the first Public Company in Electric Meters in China.2016- Acrel provided users many kinds of cloud platform.

Product Line

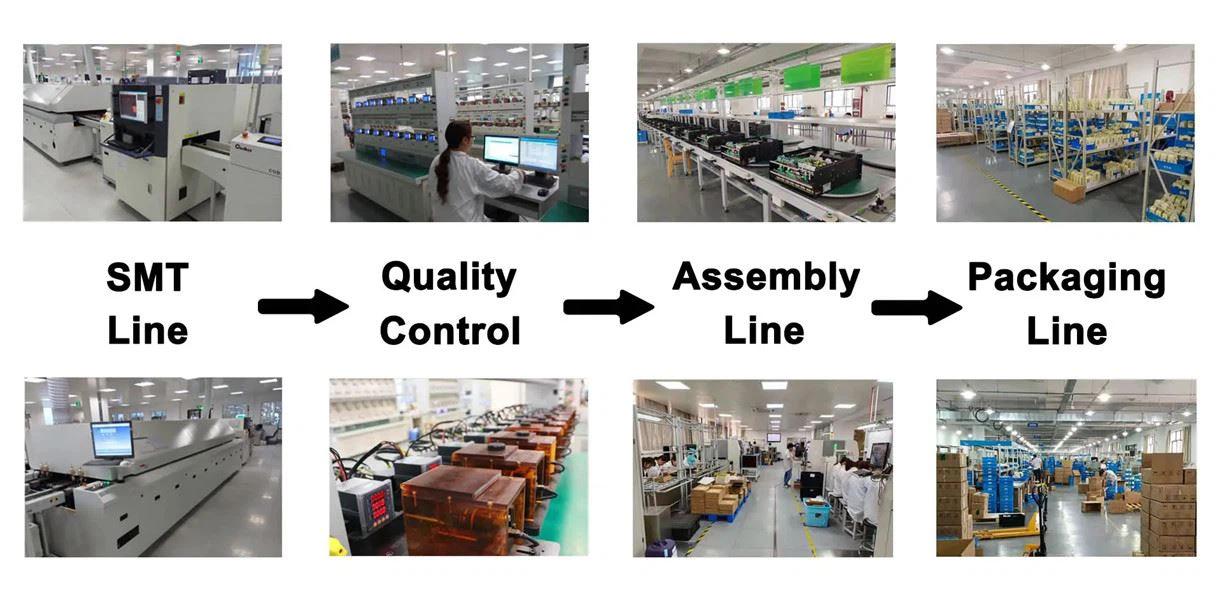

Surface Mount Technology SMT

SMT, called "Surface Mount Technology", is a circuit assembly technology for attaching and soldering surface mount components to a specified position on the surface of a printed circuit board. Drilling without principle. Specifically, it is to first apply solder paste on the printed circuit board, and then accurately place the surface mount components on the solder paste-coated pads, and heat the printed circuit board until the solder paste melts and cools down. After that, the interconnection between the components and the printed circuit board is realized. Acrel owns 8 SMT production lines for mass production of surface mount technology components in the electric meter manufacturing plant. The price has dropped significantly. Various equipment with good technical performance and low price has been launched. Electronic products assembled with SMT have It has the advantages of small size, good performance, complete functions, and low price

Test Center

-

EMC Test

-

RoHS Test

-

IP Level Test

-

Glow-wire Flammability Test

-

Environment Test

-

Salt Spray Test

-

Impact Test

-

Reliability Test

Test Standard

In Acrel production base has a self EMC test center, also called electromagnetic compatibility (EMC), which refers to the comprehensive evaluation of the electromagnetic field interference (EMI) and anti-interference ability (EMS) of electronic products, which is the product quality One of the most important indicators, the measurement of electromagnetic compatibility is composed of test sites and test instruments.

The purpose of EMC testing is to detect the influence of electromagnetic radiation generated by electrical products on the human body, the power grid in public places, and other electrical products that work normally. In the Acrel EMC test center, the meter will conduct various tests that comply with EMC standards

Radiated,radio-frequency,electromagnetic field immunity test:

the IEC 61000-4-3 .

Conducted Emission test:

1. IEC 61000-4-6

2. CISPR 22

Surge immunity test :

IEC 61000-4-5 < Electromagnetic compatibility (EMC) - Part 4-5: Testing and measurement techniques -Surge Test and Measurement Techniques>

Communication wave surge test

● IEC 61000-4-5 < Electromagnetic compatibility (EMC) - Part 4-5: Testing and measurement techniques -Surge Test and Measurement Techniques >

● FCC part68 < Connection of Terminal Equipment to the Telephone Network >

Impulse current test

● IEC 61000-4-5 < Electromagnetic compatibility (EMC) - Part 4-5: Testing and Measurement Techniques -Surge Test and Measurement Techniques >

● UL1449

Electrostatic discharge immunity test

● IEC 61000-4-2 < Electromagnetic compatibility (EMC) - Part 4-2: Testing and Measurement Techniques – Electrostatic discharge immunity test >

Electrical fast transient/burst immunity test

● IEC 61000-4-4 < Electromagnetic compatibility (EMC) - Part 4-4: Testing and Measurement Techniques –Electrical fast transient/burst immunity test >

Environment Test

.

Cold

It is used to determine the adaptability of components, equipment, or other products under low-temperature conditions for use, transportation, or storage.

standard:

● IEC 60068-2-1 < Environmental testing-Part2-1:Tests-Test A: Cold >

Dry Heat

Used to determine the adaptability of components, equipment, or other products under high-temperature conditions for use, transportation, or storage.

standard:

● IEC 60068-2-2 < Environmental testing- Part 2-2:Tests- Test B: Dry heat >

Damp Heat, Steady Stat

It is used to determine the adaptability of components, equipment, or other products for use, transportation, or storage under high humidity conditions.

standard:

● IEC 60068-2-78 < Environmental testing- Part 2-78:Tests- Test Cab: Damp heat, steady stat >

Damp Heat,Cyclic(12h+12h cycle)

It is used to determine the adaptability of components, equipment or other products under the conditions of high humidity and temperature cyclical changes, which will usually produce condensation on the surface of the test sample, for use, transportation or storage.

standard:

● IEC 60068-2-30 < Environmental testing- Part 2-30:Tests- Test Db: Damp heat,cyclic(12h+12h cycle)>

Salt Mist

It is suitable for verifying the resistance of electrical equipment or components in a salty atmosphere, and simulating the durability of electrical equipment or components used in the marine environment, coastal areas, or directly / indirectly exposed to the above areas.

Standard:

● IEC 60068-2-11 < Basic environmental testing procedures- Part 2:Tests- Test Ka: Salt mist, IDT >

Achievements