Why Need To Use Partial Discharge Detector

At this stage, metal-enclosed switchgear is widely used in the power system, so the stability and reliability of the switchgear operation is the top priority. Defects such as bubble gaps, impurities, spikes and other defects in the insulation of medium-voltage electrical equipment make the electric field distribution inside the insulation of the switch cabinet uneven under the action of strong electric field, and

the electric field strength in the defective part will increase, which will easily lead to the discharge of the part that does not penetrate the entire insulation, that is, partial discharge. Partial discharge generally does not cause the penetrating breakdown of the internal insulation of the switchgear, but it can lead to local damage to the insulating medium. If it exists for a long time, it will cause the destruction of the electrical strength of the insulation device under certain conditions, and eventually cause the insulation breakdown

inside the switchgear. For electrical equipment, partial discharge of electrical equipment is one of the important reasons for the aging or deterioration or even damage of its insulation, resulting in equipment damage and power system accidents, and it is also a sign of degradation of equipment insulation integrity.

Accidents caused by switch cabinet insulation

Accidents caused by switch cabinet insulation

White powdery corrosion products produced by corona discharge

White powdery corrosion products produced by corona discharge

Cable insulation breakdown caused by cavitation discharge

Cable insulation breakdown caused by cavitation discharge

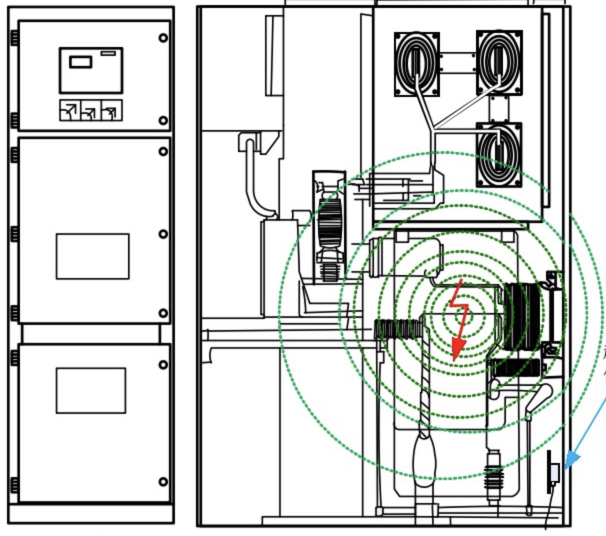

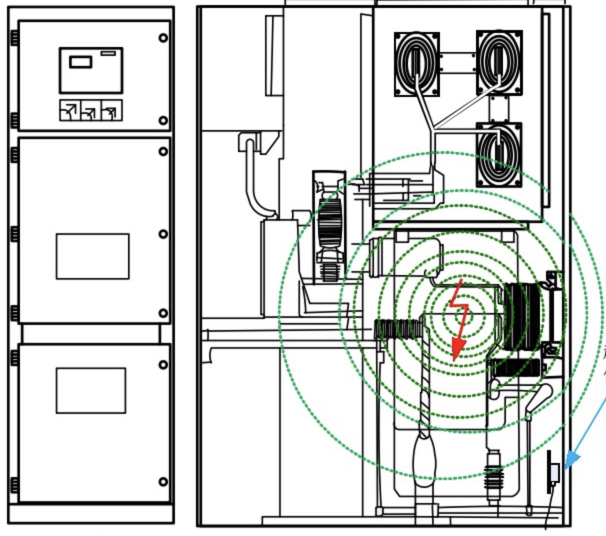

How Acrel APD300 Working

-

Partial discharge phenomenon in switchgear

When partial discharge occurs in electrical equipment, it is accompanied by a series of physical phenomena such as electricity, light, sound, and heat. Therefore, the monitoring and inspection methods for partial discharge in high-voltage switchgear are all carried out based on detecting these physical quantities that can reflect the partial discharge phenomenon.

-

Partial discharge monitoring methods for switchgear: acoustic wave

The Transient Earth Voltage (TEV) method is based on Maxwell's electromagnetic field theory. When partial discharge occurs in a high-voltage switchgear, it will generate an alternating electromagnetic field and excite electromagnetic waves. The electromagnetic wave signals will propagate inside the cabinet and leak to the cabinet shell at places where the shielding is discontinuous. The leaked electromagnetic wave signals will induce an induced current on the shell, and form a pulse voltage through the wave impedance existing on the surface of the equipment, which is the transient earth voltage signal, referred to as TEV for short.

-

Partial discharge monitoring methods for switchgear: transient earth voltage

The ultrasonic detection method utilizes the fact that partial discharge occurs in a relatively short time with high instantaneous power. The released energy will be absorbed by the surrounding medium in the form of heat. After being heated, the molecules will form a sound source and generate ultrasonic signals. Due to the short discharge time, the generated sound waves have a very wide frequency spectrum. The ultrasonic signals propagate in the switchgear cabinet, are received by the piezoelectric crystal of the sensor and converted into electrical signals, which are then further amplified and collected for subsequent analysis.

-

Partial discharge monitoring methods for switchgear: ultra-high frequency

The theoretical basis of the ultra-high frequency method is that the electromagnetic waves excited when partial discharge occurs in the switchgear can reach a maximum frequency of up to the GHz level. The electromagnetic signals at this frequency can be received by the antenna sensor installed in the switchgear, so as to further analyze the signals and determine the fault type and fault distance, etc.

Acrel APD300 Function

Parameter

APD300-L

Power

DC 9-36V

Communication

RS485(MODBUS-RTU)

Sampling

4s

PD Monitoring Sensors

Ultrasonic Sensors (AE)

Measuring range

0~70dBμV

Resonant frequency

40kHz±1kHz

Ground Wave Sensors (TEV)

Resonant frequenc

Measuring range

0~60dBmV

Bandwidth

3MHz~100MHz

Ultra-High Frequency Sensors (UHF)

Measuring range

-70~10dBm

Bandwidth

300MHz~1500MHz

Average Equivalent Height

≥10mm

Environment

Noise measuring range

30dB~130dB

Temp measuring range

-40℃~85℃

Humidity Measuring Range

0~100%RH

Usage Environment

Temperature

-40℃~85℃

Relative humidity

≤95%RH

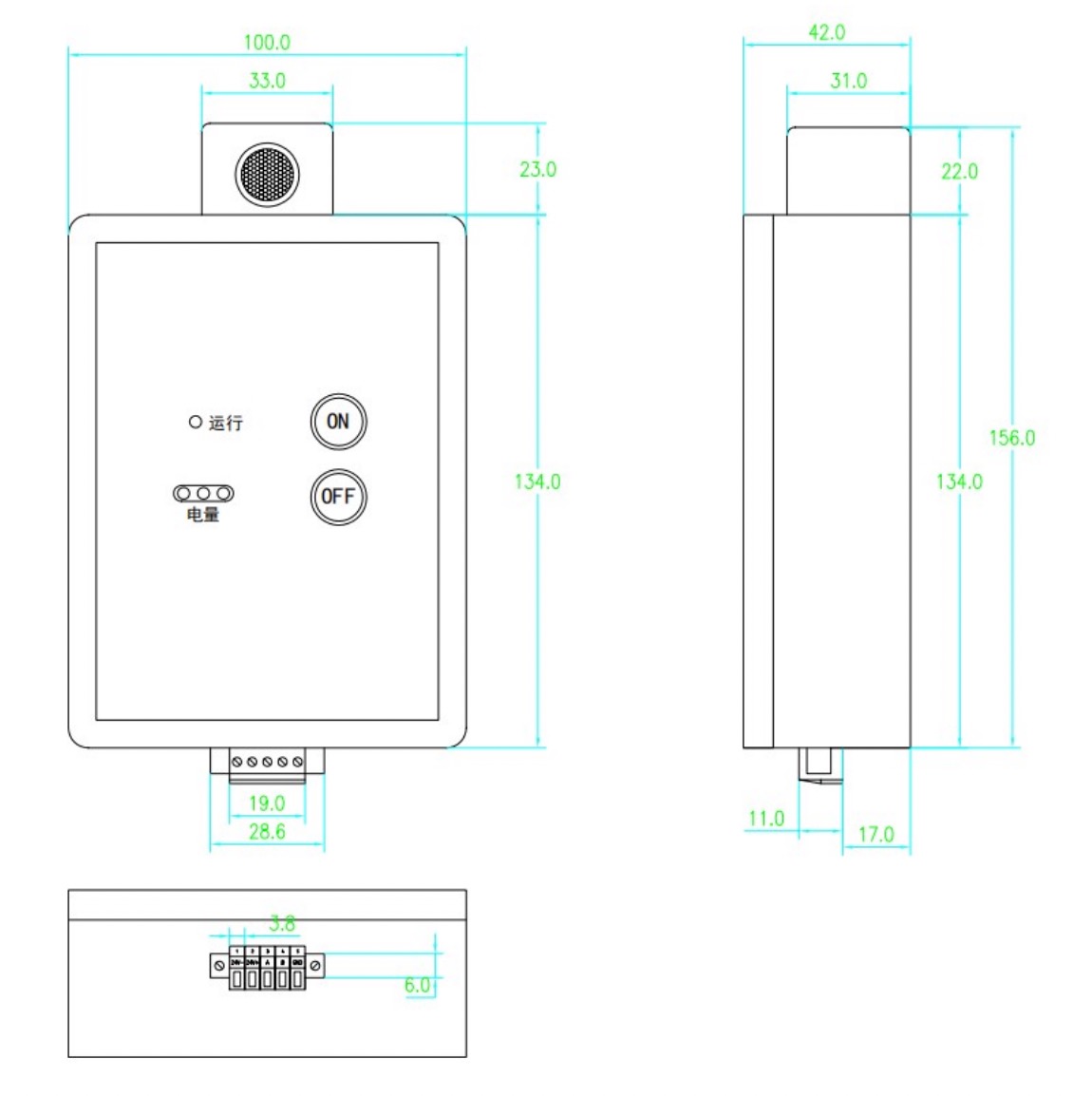

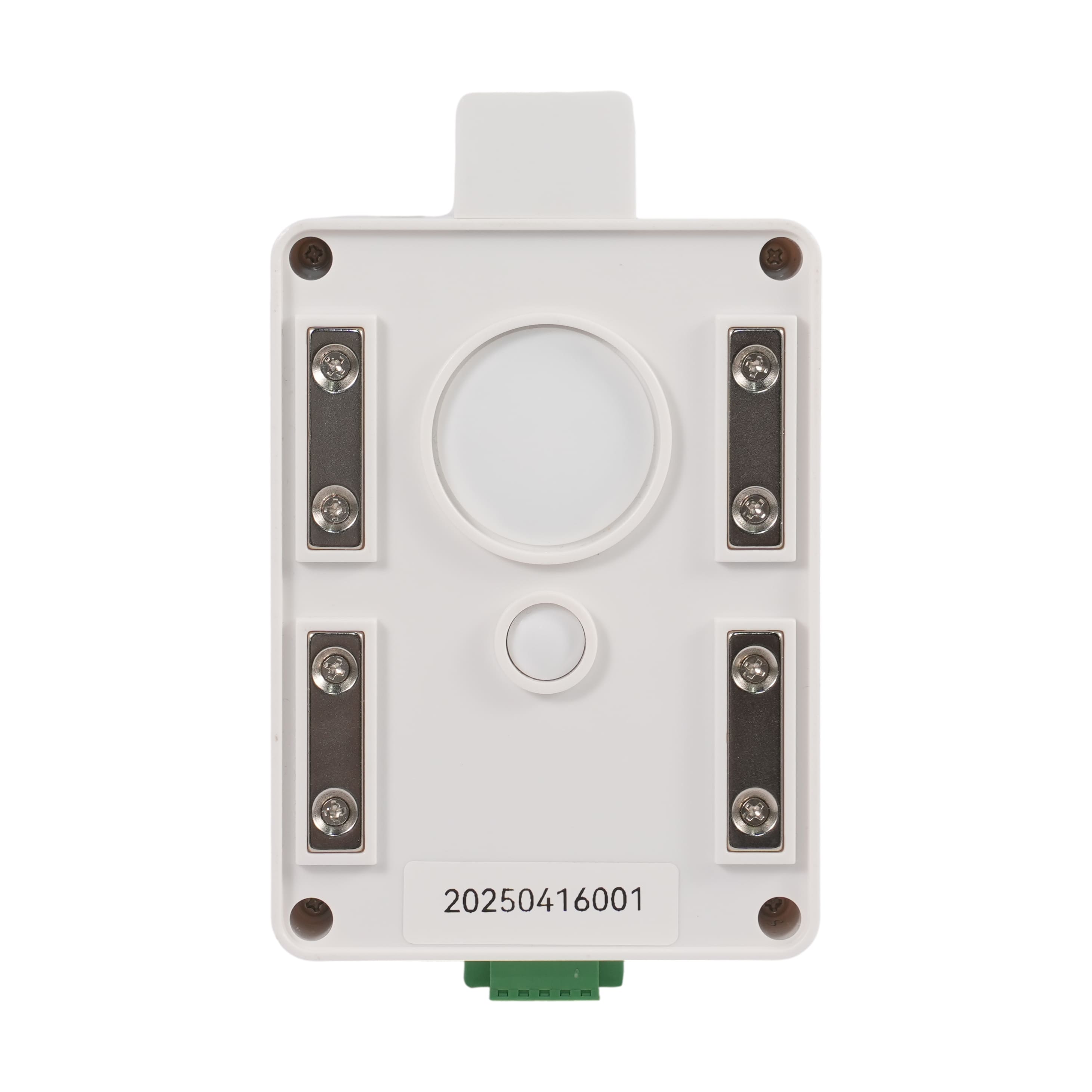

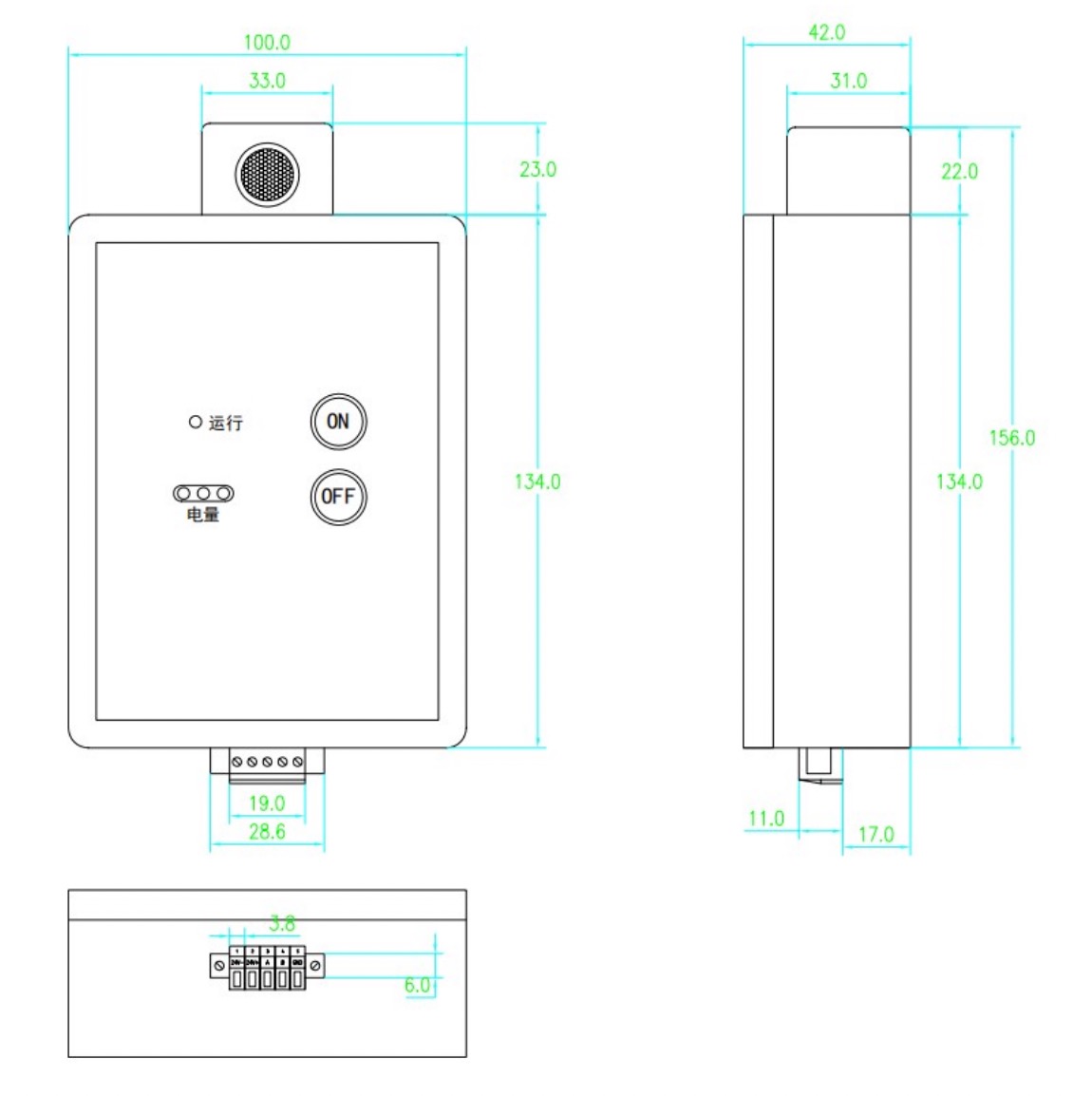

Dimensions

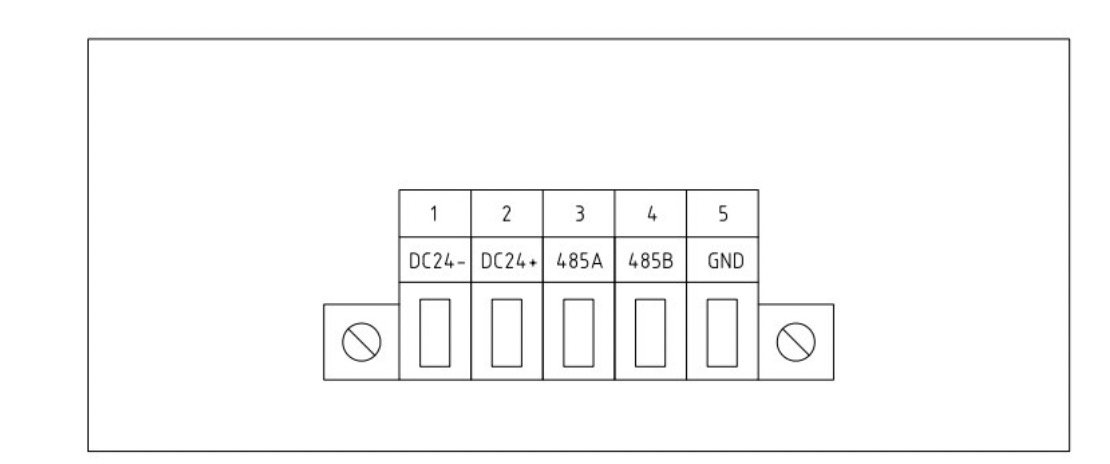

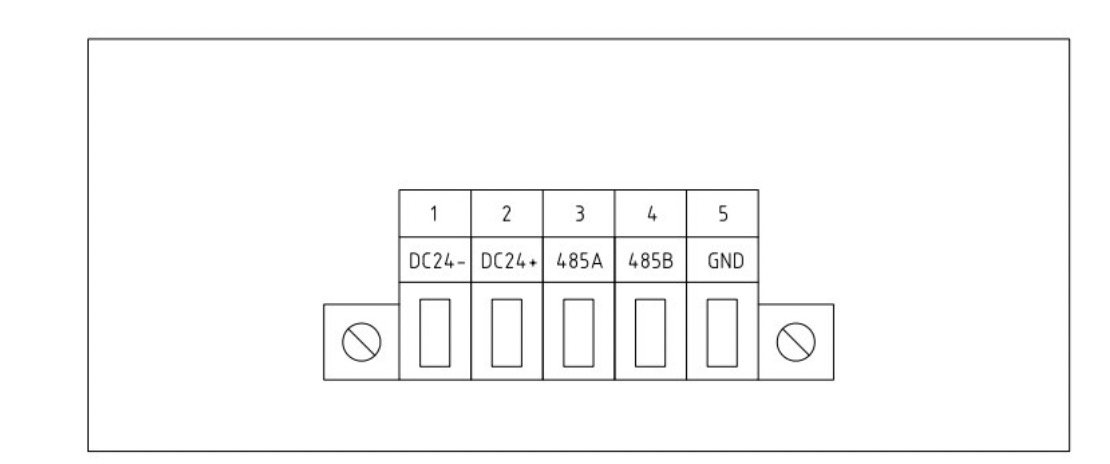

Wiring

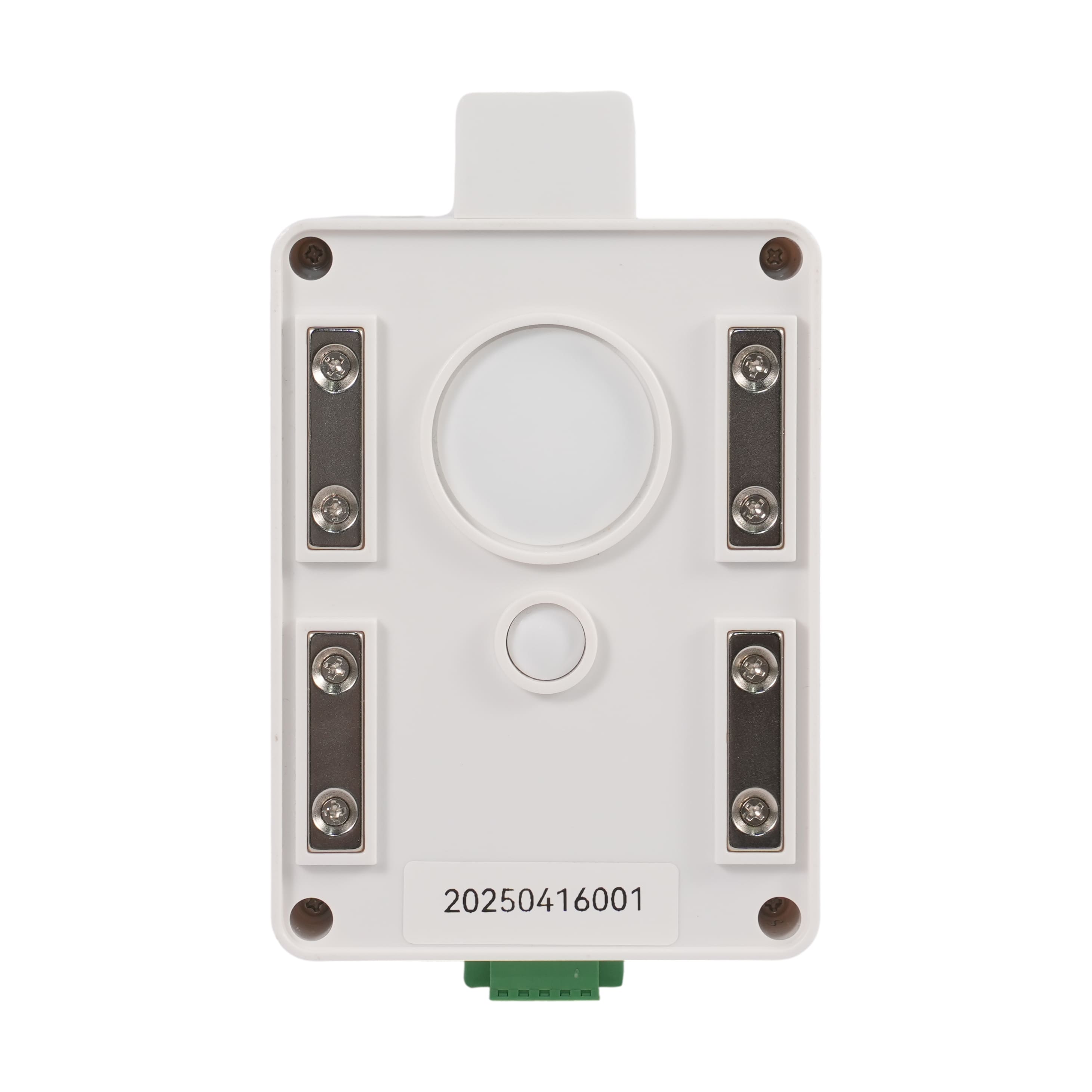

Site Photo

Why Need To Use Partial Discharge Detector

At this stage, metal-enclosed switchgear is widely used in the power system, so the stability and reliability of the switchgear operation is the top priority. Defects such as bubble gaps, impurities, spikes and other defects in the insulation of medium-voltage electrical equipment make the electric field distribution inside the insulation of the switch cabinet uneven under the action of strong electric field, and

the electric field strength in the defective part will increase, which will easily lead to the discharge of the part that does not penetrate the entire insulation, that is, partial discharge. Partial discharge generally does not cause the penetrating breakdown of the internal insulation of the switchgear, but it can lead to local damage to the insulating medium. If it exists for a long time, it will cause the destruction of the electrical strength of the insulation device under certain conditions, and eventually cause the insulation breakdown

inside the switchgear. For electrical equipment, partial discharge of electrical equipment is one of the important reasons for the aging or deterioration or even damage of its insulation, resulting in equipment damage and power system accidents, and it is also a sign of degradation of equipment insulation integrity.

Accidents caused by switch cabinet insulation

White powdery corrosion products produced by corona discharge

Cable insulation breakdown caused by cavitation discharge

How Acrel APD300 Working

-

Partial discharge phenomenon in switchgearWhen partial discharge occurs in electrical equipment, it is accompanied by a series of physical phenomena such as electricity, light, sound, and heat. Therefore, the monitoring and inspection methods for partial discharge in high-voltage switchgear are all carried out based on detecting these physical quantities that can reflect the partial discharge phenomenon.

-

Partial discharge monitoring methods for switchgear: acoustic waveThe Transient Earth Voltage (TEV) method is based on Maxwell's electromagnetic field theory. When partial discharge occurs in a high-voltage switchgear, it will generate an alternating electromagnetic field and excite electromagnetic waves. The electromagnetic wave signals will propagate inside the cabinet and leak to the cabinet shell at places where the shielding is discontinuous. The leaked electromagnetic wave signals will induce an induced current on the shell, and form a pulse voltage through the wave impedance existing on the surface of the equipment, which is the transient earth voltage signal, referred to as TEV for short.

-

Partial discharge monitoring methods for switchgear: transient earth voltageThe ultrasonic detection method utilizes the fact that partial discharge occurs in a relatively short time with high instantaneous power. The released energy will be absorbed by the surrounding medium in the form of heat. After being heated, the molecules will form a sound source and generate ultrasonic signals. Due to the short discharge time, the generated sound waves have a very wide frequency spectrum. The ultrasonic signals propagate in the switchgear cabinet, are received by the piezoelectric crystal of the sensor and converted into electrical signals, which are then further amplified and collected for subsequent analysis.

-

Partial discharge monitoring methods for switchgear: ultra-high frequencyThe theoretical basis of the ultra-high frequency method is that the electromagnetic waves excited when partial discharge occurs in the switchgear can reach a maximum frequency of up to the GHz level. The electromagnetic signals at this frequency can be received by the antenna sensor installed in the switchgear, so as to further analyze the signals and determine the fault type and fault distance, etc.

Acrel APD300 Function

|

Parameter |

APD300-L | ||

| Power |

DC 9-36V

|

||

| Communication | RS485(MODBUS-RTU) | ||

| Sampling | 4s | ||

| PD Monitoring Sensors | Ultrasonic Sensors (AE) | Measuring range | 0~70dBμV |

| Resonant frequency | 40kHz±1kHz | ||

|

Ground Wave Sensors (TEV)

Resonant frequenc

|

Measuring range | 0~60dBmV | |

|

Bandwidth

|

3MHz~100MHz | ||

|

Ultra-High Frequency Sensors (UHF) |

Measuring range | -70~10dBm | |

| Bandwidth | 300MHz~1500MHz | ||

| Average Equivalent Height | ≥10mm | ||

| Environment | Noise measuring range | 30dB~130dB | |

| Temp measuring range | -40℃~85℃ | ||

| Humidity Measuring Range | 0~100%RH | ||

| Usage Environment | Temperature | -40℃~85℃ | |

| Relative humidity | ≤95%RH | ||

Dimensions

Wiring

Site Photo